I. Overview

II. Overview of the External View

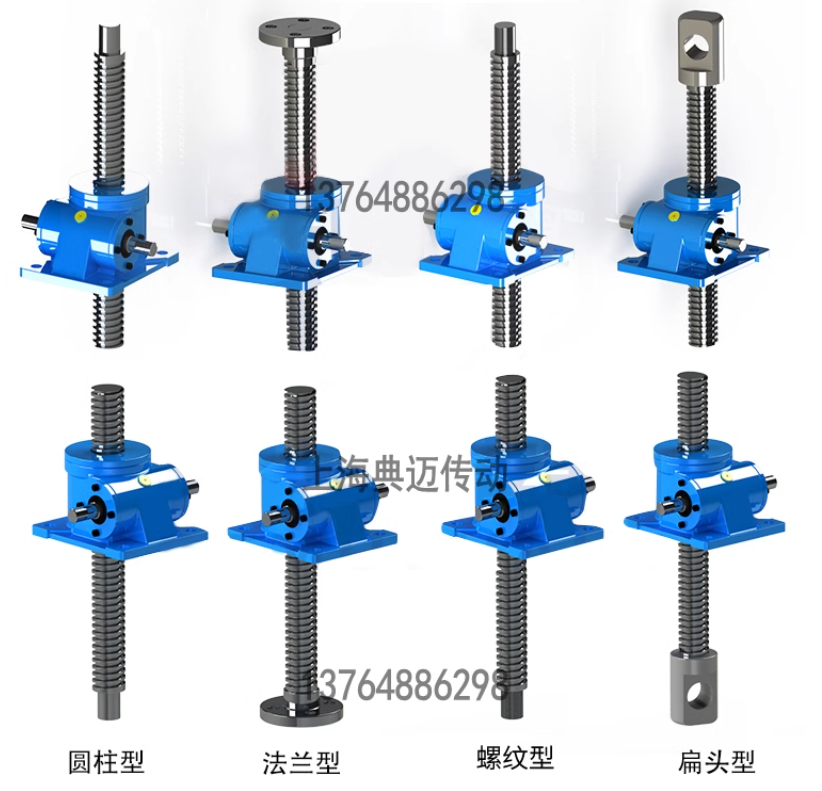

III. Structural Types

1. Type 1 – Axial Movement of the Screw

2. Type 2 – Rotational Movement of the Screw and Axial Movement of the Nut

IV. Assembly Types

1. Type A – Upward Movement of the Screw/ or Nut

2. Type B – Downward Movement of the Screw/ or Nut

V. Screw Head Types

1. Screw Heads of Type 1 Structural Type

Type I (Cylindrical):

Type II (Flanged):

Type III (Threaded):

Type IV (Flat-Head):

2. Screw Heads of Type 2 Structural Type

Type I (Cylindrical):

Type III (Threaded):

VI. Transmission Ratios

1. Ordinary Speed Ratio (P)

2. Slow Speed Ratio (M)

3. Customizable Medium Speed Ratio (F)

VII. Lifting Capacity

VIII. Protection of the Screw

1. Type 1 Structure

Basic Type (No Protection):

Anti-Rotation Type (F):

With Protective Cover (Z):

Anti-Rotation with Protective Cover (FZ):

2. Type 2 Structure

Basic Type (No Protection):

IX. Conclusion